Air compressors are extremely useful tools for both household and industrial applications. However, they often generate high noise levels that can disrupt work and living spaces. Excessive exposure to loud air compressor noise poses the risk of long-term hearing damage as well.

Fortunately, there are several methods you can use to make an air compressor quieter without affecting performance.

This guide covers various noise reduction solutions, from simple positioning tweaks to upgrading components. With a few modifications, you can use your air compressor without all the racket.

What Causes Air Compressors to Be So Loud

To understand how to quiet an air compressor, you first need to know what makes them loud in the first place. An air compressor works by drawing air in through an intake valve, compressing it to higher pressures using a motor-driven pump, and expelling the compressed air out the discharge valve and hose.

The main culprits contributing to air compressor noise are:

- Vibrations from pump and motor – These vibrate against the housing, amplifying sound.

- Intake suction noise – Large volumes of air get sucked in through the intake valve.

- Discharge air noise – Pressurized air gets expelled forcefully through small exhaust holes and hoses.

- Amplification from hard surfaces – The high pressures cause compressor surfaces to vibrate, transmitting noise.

In general, larger capacity and higher pressure compressors produce more noise, exceeding 100 dB. This is as loud as a motorcycle or lawnmower running constantly!

Now that you know what factors account for air compressor noise, let’s explore solutions to address each one.

5 Tips to Make an Air Compressor Quieter

There are several ways you can help make an air compressor quieter to reduce noise pollution and potential hearing loss. The solutions range from simple fixes to extensive upgrades:

Improving Location

Where you operate the air compressor significantly impacts the perceived noise levels. Some easy location adjustments include:

- Place the compressor as far away from work and living areas as possible – Every foot of distance will reduce noise to some degree.

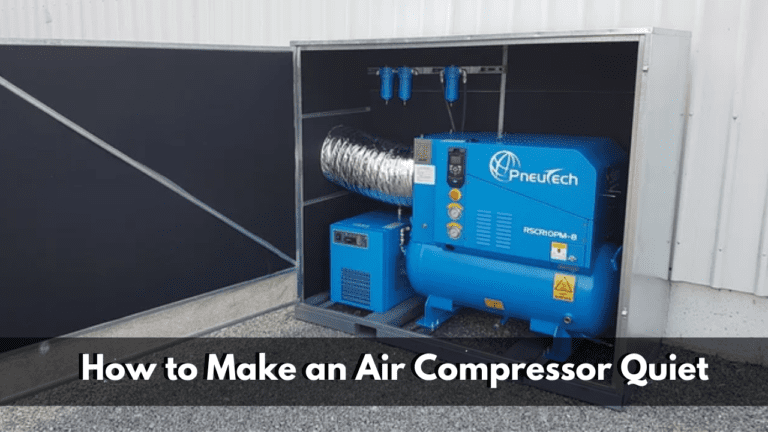

- Build an insulated external enclosure – A sound-damping enclosure around the compressor can reduce noise by up to 50%. Use soundproofing insulation boards and mass loaded vinyl barriers.

- Use vibration damping pads – Installing the compressor on anti-vibration pads absorbs mechanical noise and structure-borne vibration transmission.

Upgrading Compressor Components

You can replace standard compressor parts with quieter versions:

- Install a quieter pump and motor combination – Look for models designed for low-speed operation under 60dBA.

- Add sound dampening materials – Lining the inside covers with acoustic foam effectively absorbs noise.

- Use a quieter drive system – Direct drive compressors avoid the mechanical noise associated with belt drive systems.

Intake and Exhaust Modifications

Noise escapes from the intake and exhaust systems. To mitigate this:

- Add mufflers to the intake and exhaust – These minimize air movement noise at inlet and outlet points. Opt for high-density muffler materials rated to withstand pressure.

- Lengthen input and output hoses – Increases distance between noise source and human ears.

- Direct exhaust away from occupied spaces – Route exhaust hoses to project air noise to uninhabited areas. Consider using flexible exhaust ducting.

Regular Maintenance

It’s surprising how routine maintenance can also help quiet your air compressor:

- Keep components well lubricated – Adequate lubricant reduces friction and vibration between moving metal parts.

- Inspect for air leaks or damage – Small leaks or loose panels can allow noise to easily escape.

- Tighten fasteners and hose connections – Secure all nuts, bolts, parts that can rattle and transmit noise.

- Replace worn out parts – Fix any failing pump and motor components making excessive noise.

Additional Noise Control Options

Along with modifications directly on the air compressor unit, also consider:

- Build a full sound dampening enclosure – A properly constructed soundproof box can block almost all noise.

- Wear noise cancelling ear muffs – Protect your hearing when working near constantly running compressors.

- Restrict high noise tasks to certain times – Be considerate of neighbors with evening/weekend compressor operation.

Choosing a Quieter Compressor Model

If you plan to purchase a new air compressor, look for models designed for quiet operation:

- Check the noise level ratings – Compare decibel ratings (dB) from various manufacturers.

- Consider noise design in components – Units with quiet motors, pumps, drive systems produce less inherent noise.

- Research sound dampening features – Some come equipped with acoustic enclosures and insulation.

Recommended Quiet Compressor Models

Here are some of the quietest air compressor models on the market:

- California Air Tools Ultra Quiet Series (60 dB rating)

- Rolair JC10 Plus 2HP 60-Gallon Electric (62 dB rating)

Read : How To Use Your Phone In The Shower

Conclusion – How to make an air compressor quiet

There are many solutions, ranging from simple to advanced, to help make an air compressor quieter. With some planning, upgrades, and regular maintenance, you can use your compressor without all the racket disturbing your household or workplace.

Just be cautious handling any acoustic modifications on a compressor used for critical applications. Consider consulting an HVAC specialist for guidance on more involved quieting projects.

Implementing noise reduction measures allows you to reap the utility benefits of an air compressor while also being considerate of noise pollution impacts. A little time, effort, and investment into quieting solutions goes a long way to improve quality of life and work.

Frequently Asked Questions

Q: How much quieter will a sound enclosure make my air compressor?

A: Properly constructed sound enclosures with acoustic insulation can reduce air compressor noise by up to 50 decibels. This can make a tremendously positive impact on sound levels.

Q: What are the best materials for making a DIY soundproof enclosure?

A: Mass loaded vinyl, MLV blocks the most sound transmission. Pair it with acoustic foam and insulation boards rated for exterior use. Solid wood or plywood also helps contain noise.

Q: Is there a big difference in noise levels between belt drive vs direct drive compressors?

A: Yes, direct drive models have fewer moving parts and avoid the mechanical noise from belts. They offer quieter operation.

Q: Does lubricating the compressor help reduce noise?

A: Yes, keeping all moving components properly oiled or greased ensures smooth operation and less vibration and friction noise.

Q: Should I get a large or small air tank if I want a quiet compressor?

A: Larger air tank capacities are generally quieter since they allow the motor to run less frequently to maintain pressure. This gives your ears a break from constant noise.